Product application

The vertical H beam welding line can be used for the construction industry. The color plate can be used for the roof and wall; the thin-wall steel section can be used for purlin and ring beam; the welded H section can be used for the main beam. And the main structure of the building is portal frame which is connected by bolt or welding on site. And it is also equipped with some parts, fasteners, doors and windows, forming a relatively perfect building system.

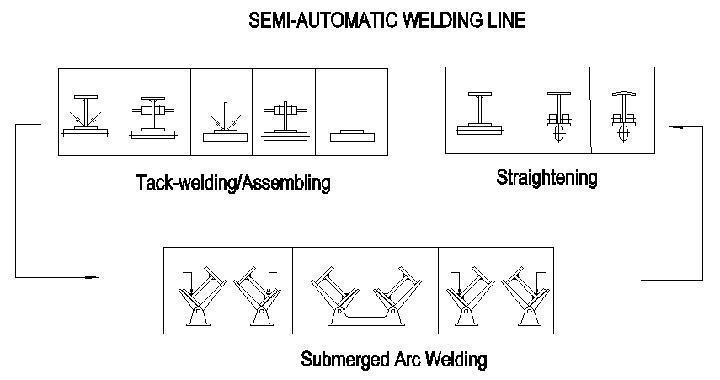

Production line flow

Cutting → T shape assembly → 90 degree hydraulic turnover → H shape assembly → 90 degree turnover → roller conveyor transport → seam welding → 45 degree hydraulic tilting → translation → 45 degree hydraulic tilting → 45 degree hydraulic replacing → roller conveyor transport → 180 degree hydraulic turnover → roller conveyor transport → 180 degree hydraulic turnover → roller conveyor transport → 45 degree hydraulic tilting → 45 degree hydraulic replacing → translation → 45 degree hydraulic tilting → 45 degree hydraulic replacing → translation → 90 degree hydraulic turnover → flange straightening 1 → 180 degree hydraulic turnover → flange straightening 2 → hoisting.

Features

The vertical H beam welding line has the following features:

1. Compared with the general structural steel production line, it is equipped with additional 90 degree steel beam overturn equipment, 45 degree steel beam tilting equipment, track cart conveyor, 180 degree hydraulic steel beam overturn equipment and roller conveyor to realize automatic production of steel H beam, production safety improving and labor intensity reducing.

2. The assembly machine can be equipped with gas shielded arc welding from either international brand such as Lincoln electric or Chinese brand with higher cost performance. It can also be equipped with customers' appointed welding machine. So our after-sales service can be the fastest and cheapest.

3. The centering method of the web and flange plate adopts three groups of centering devices both forward and backward. So that the positioning precision is improved.

4. Welding post: 4 cantilever welding base machines can be equipped with 4 to 8 welding sources. It can also be equipped with track cart conveyor for feeding and automatic steel beam overturn equipment. So it can realize highly efficient fillet welding in the flat position.

5. It adopts imported PLC control with reliability and easy programming.

6. The complete production line covers an area of 144mx14.5m. It can be U-shape or L-shape arranged according to the customers' factory.

Jinfeng introduction

Jinfeng Welding & Cutting Machinery Manufacture Co., Ltd has mechanical department, electrical department and software department. There is 80 people in the team in total. We also hire senior engineers from ESAB to carry out joint development and design of various structural steel H beam production lines, so that we have technical guarantee.

Jinfeng has strong production capacity: we have 13 imported CNC machining centers, 3 4mx12m large machining centers, so that the annual output of various assembly machine is 1000.

All the members of the sales team have more than 10 years of experience in service, so that they can provide customers with various consultation and services in time. Besides, Jinfeng is equipped with an after-sales service team of 30 employees, so that they can provide 24-hour after-sales service all year round.